WHO ARE WE

An Engineering Support Industry Leader

providing specialized

die-casting and machining solutions

We design our manufacturing processes based on the manufacturing type, technique, and technology used to cater to our customers’ product specifications and requirements. Our manufacturing processes fall into two (2) categories as follows:

(i) High-mix Low Volume (“HMLV”) manufacturing

The process of producing a high variety of products in small quantities. This production method is commonly used to manufacture unique and more complex products with specific quality requirements.

(ii) Low-mix High Volume (“LMHV”) manufacturing

The process of producing a low variety of products in large quantities. This production method is commonly used to manufacture general parts and consumables that are more frequently used and/or have a high replacement rate.

Our ability to offer both HMLV and LMHV manufacturing for a wide variety of precision engineering products is supported by the advanced machinery and robotic technology used in our manufacturing facilities.

Our Group’s history dates back to 1974 when our late founder, Dato’ Teh Ah Ba, founded Eng Hardware Electrical to undertake the manufacturing of precision engineering components.

Our extensive experience and industry insights gained throughout the years have led to the sustained growth of our business, thus allowing us to establish our reputation as a reputable manufacturer of precision engineering components, which are used for the production or assembly of finished products for various industrial applications.

SERVICES

Professionalism and Trustworthiness

New Product

Introduction

We provide prompt responses to RFQs, as well as reasonable pricing. We also offer design and process optimization services, making rapid prototypes and first products possible.

Die Casting

We produce casted aluminium components from raw aluminium ingots through the use of moulds, called dies.

Casting

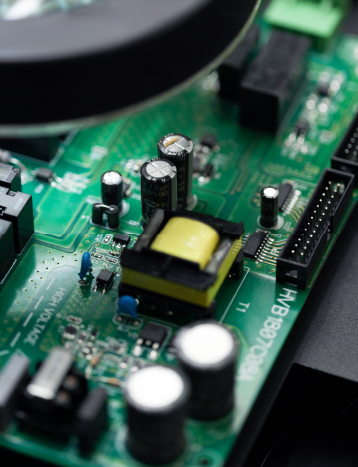

Machining

We produce precision engineering components from casted metal components through a technical and detail-oriented process called precision machining, which uses a variety of techniques and equipment to achieve precise cuts, shapes, and sizes according to the detailed specifications of our customers

Solid Machining

The strength of solid machining is that it allows it to specialise in the difficult and unusual. Thus, it can produce high-precision, high-quality parts with a wide range of features.

Laser Cutting & Bending

We provide high-precision laser cutting and bending services for sheet metal fabrication. This combination ensures accurate cuts and consistent bends, even for complex part geometries.

Welding

We provide spot welding and laser welding services for precision sheet metal assemblies. Our processes ensure clean, strong, and consistent joints, suitable for a wide range of industrial applications.

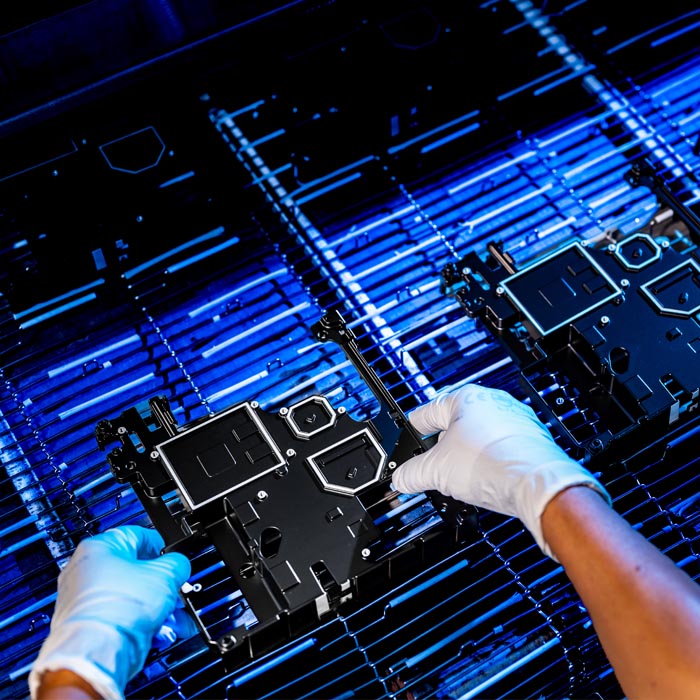

Precision Cleaning

Precision cleaning is carried out for cleanliness sensitive products to ensure we deliver the highest quality of cleanliness. Products are packed with ultra-clean packaging materials to maintain the required level of cleanliness.

Assembly & Finishing

We provide mechanical sub-assembly services, which comprise the assembly of different shapes of precision engineering components into a single precision engineering component unit, from simple to complex assemblies, such as tube insertion.

Test & Reliability

Engtek works closely with customers and suppliers to ensure its products meet uncompromising quality and reliability standards.

Interested In What You See?

BUSINESS

Precision Engineering Components That are Used in a Variety of Industrial Applications

Corporate Responsibility