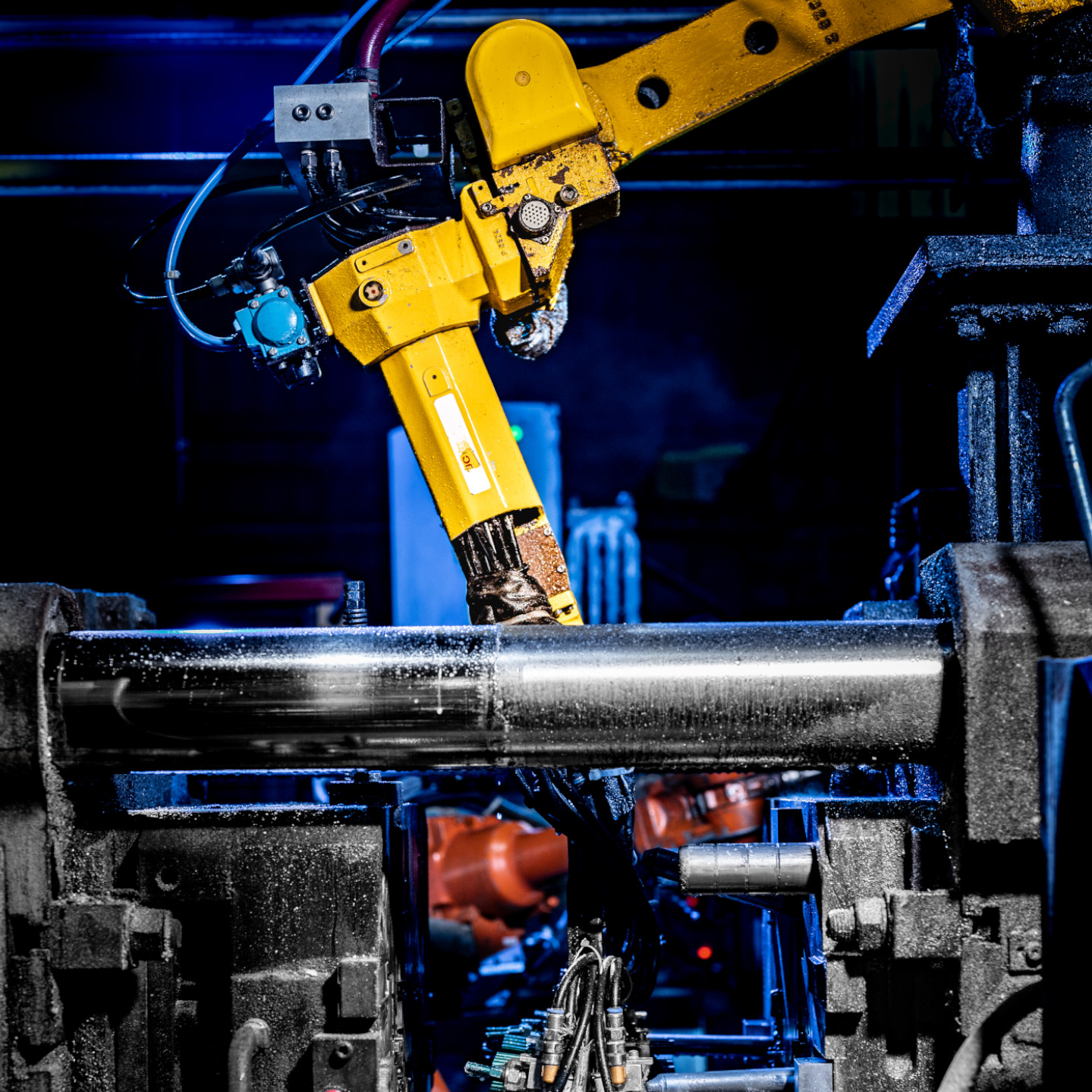

Die Casting

We understand that creating complex aluminum components with intricate shapes and fine details can be challenging. That’s why we offer a perfect solution for your manufacturing needs, with the expertise and capacity to deliver your orders on time, every time.

ENGCAST®

Die Casting

We understand that creating complex aluminum components with intricate shapes and fine details can be challenging. That’s why we offer a perfect solution for your manufacturing needs, with the expertise and capacity to deliver your orders on time, every time.

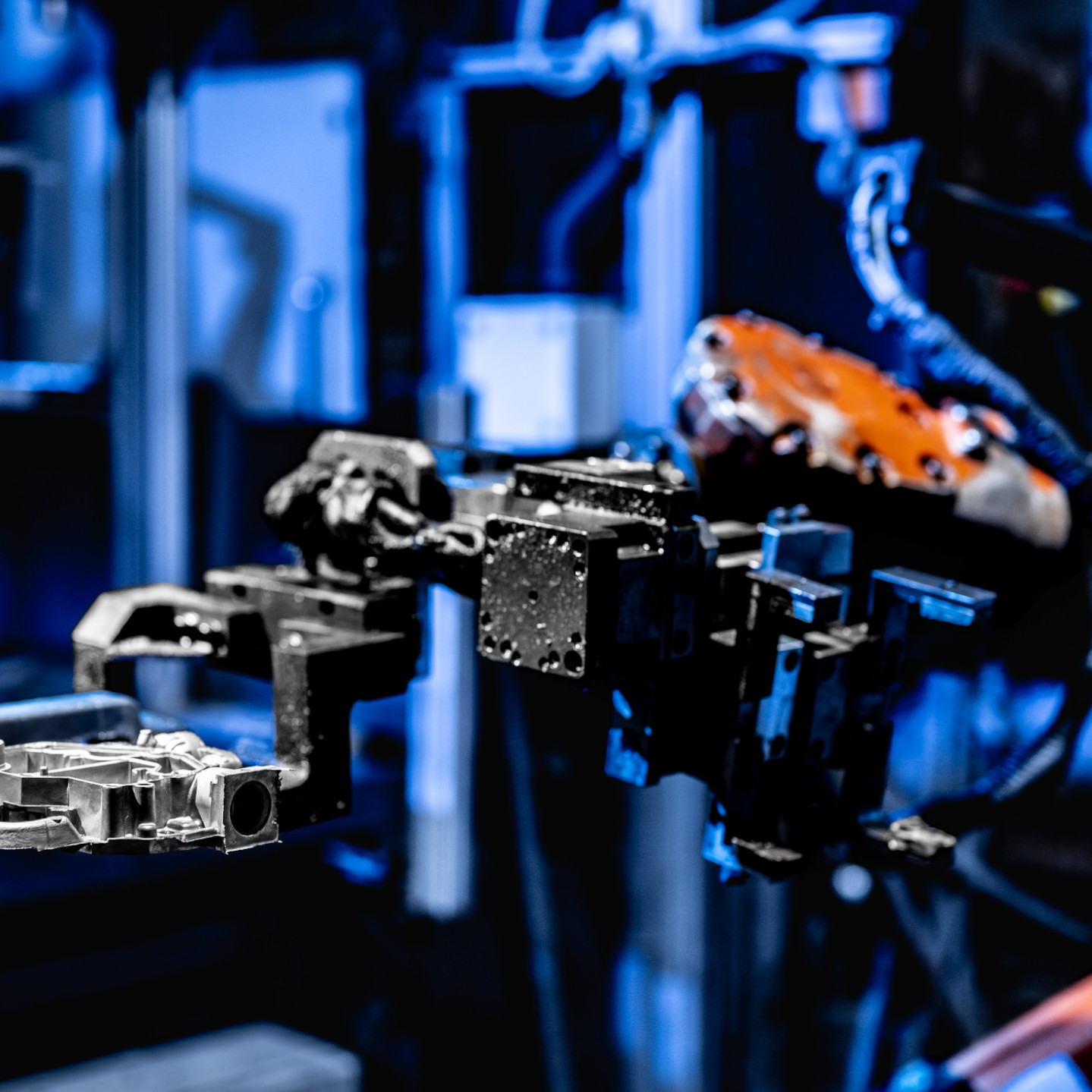

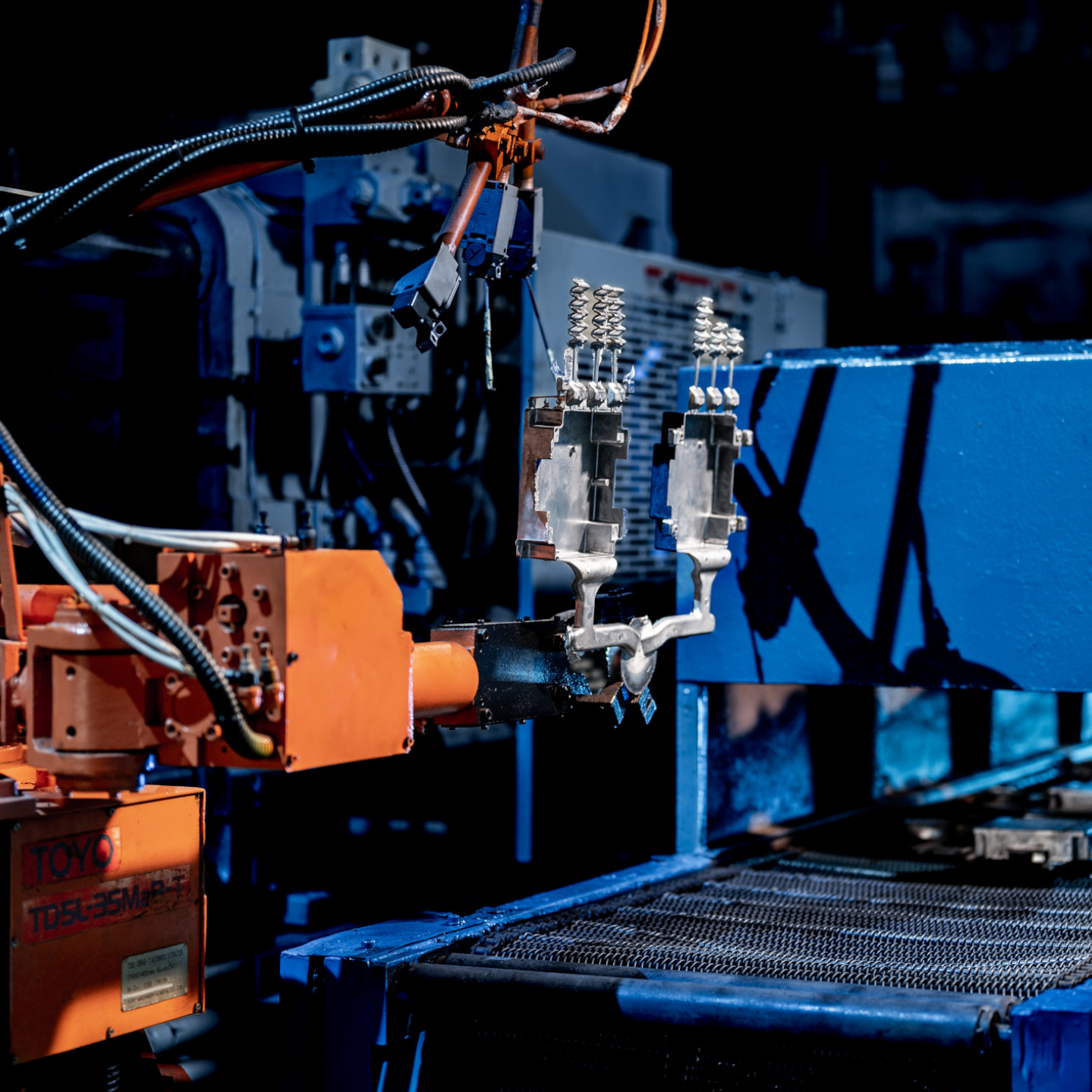

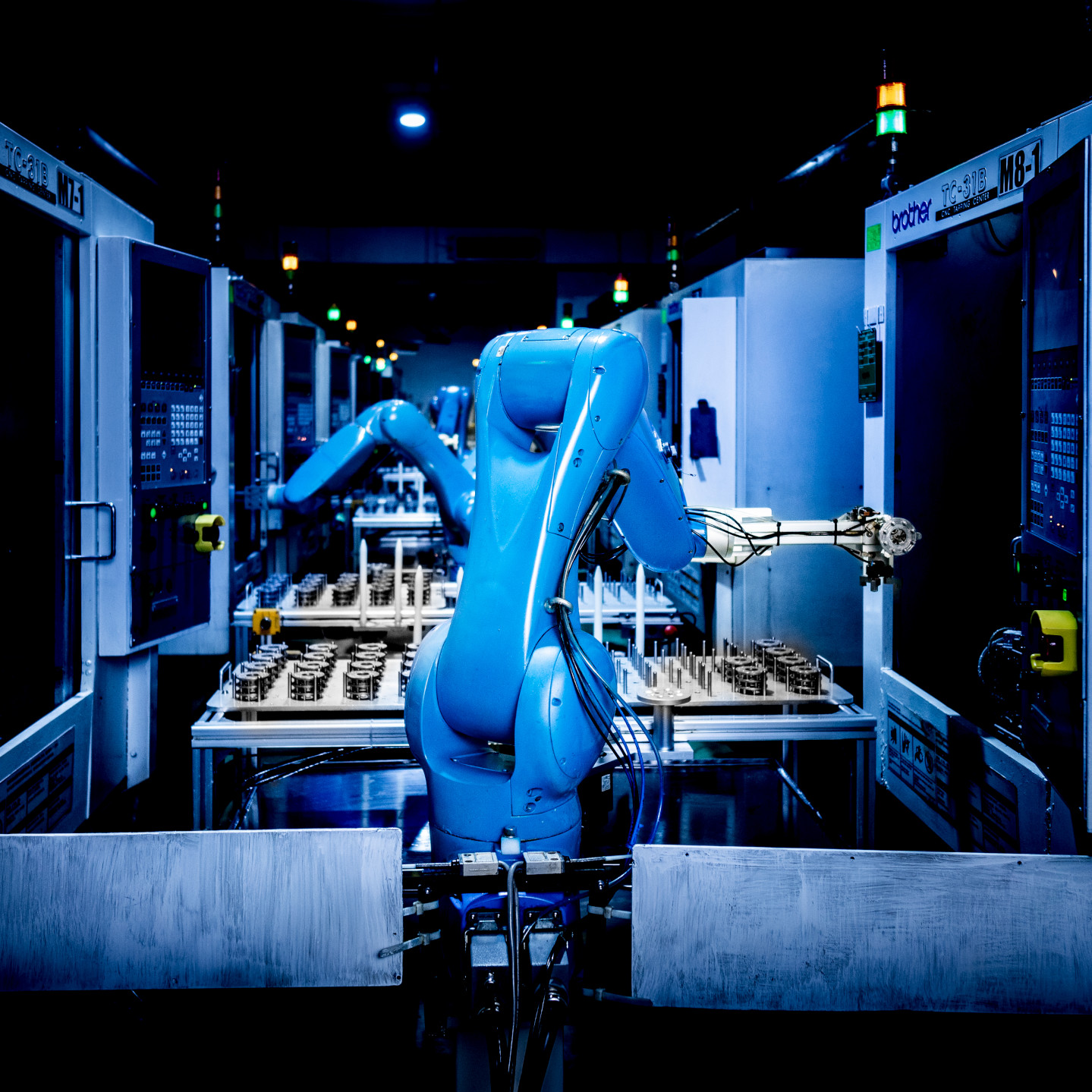

ENGMACH®

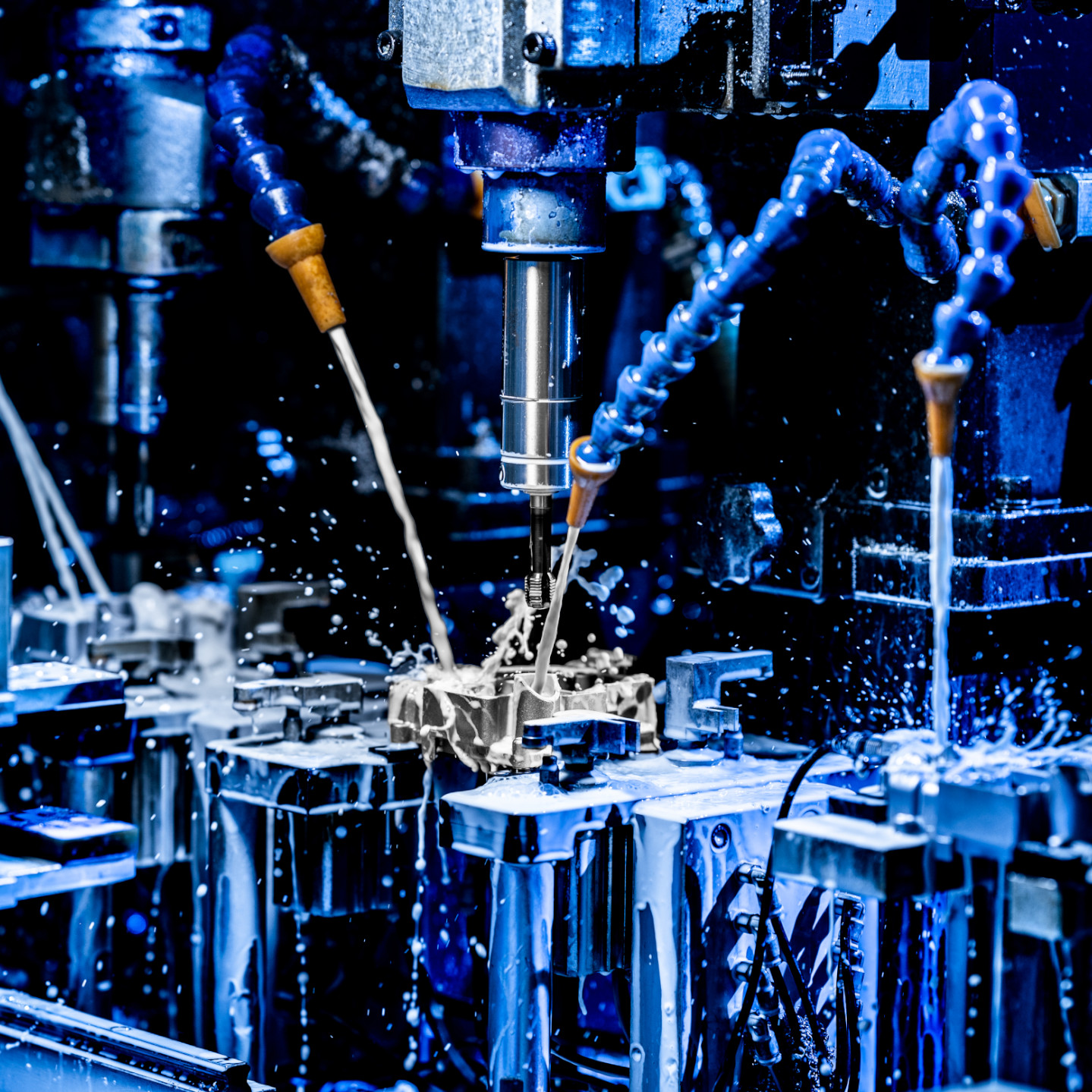

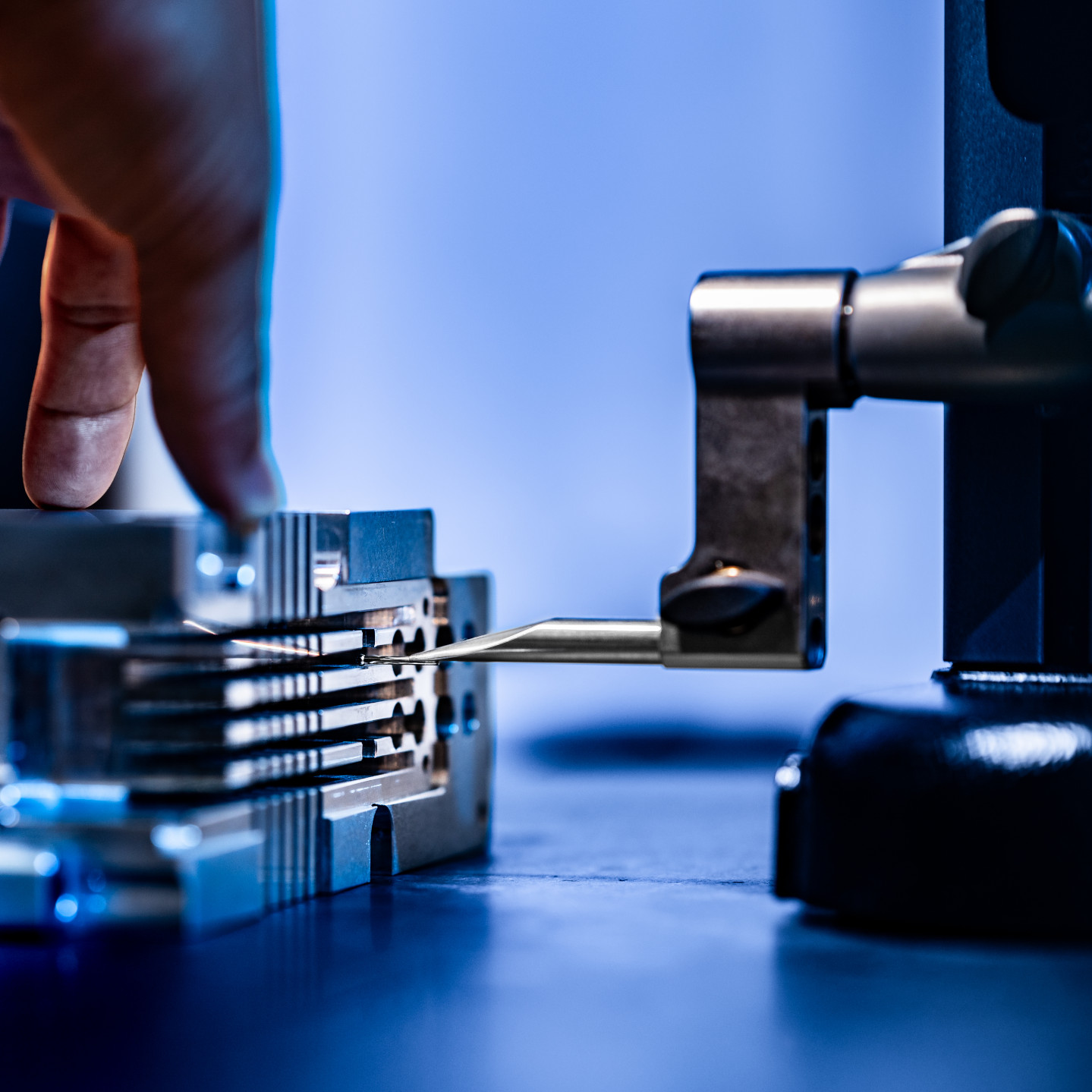

Casting CNC Machining

Transforming raw materials into engineering masterpieces requires precision and care. At Engtek, we offer post-processing CNC machining services to produce high-quality cast parts to your exact specifications.

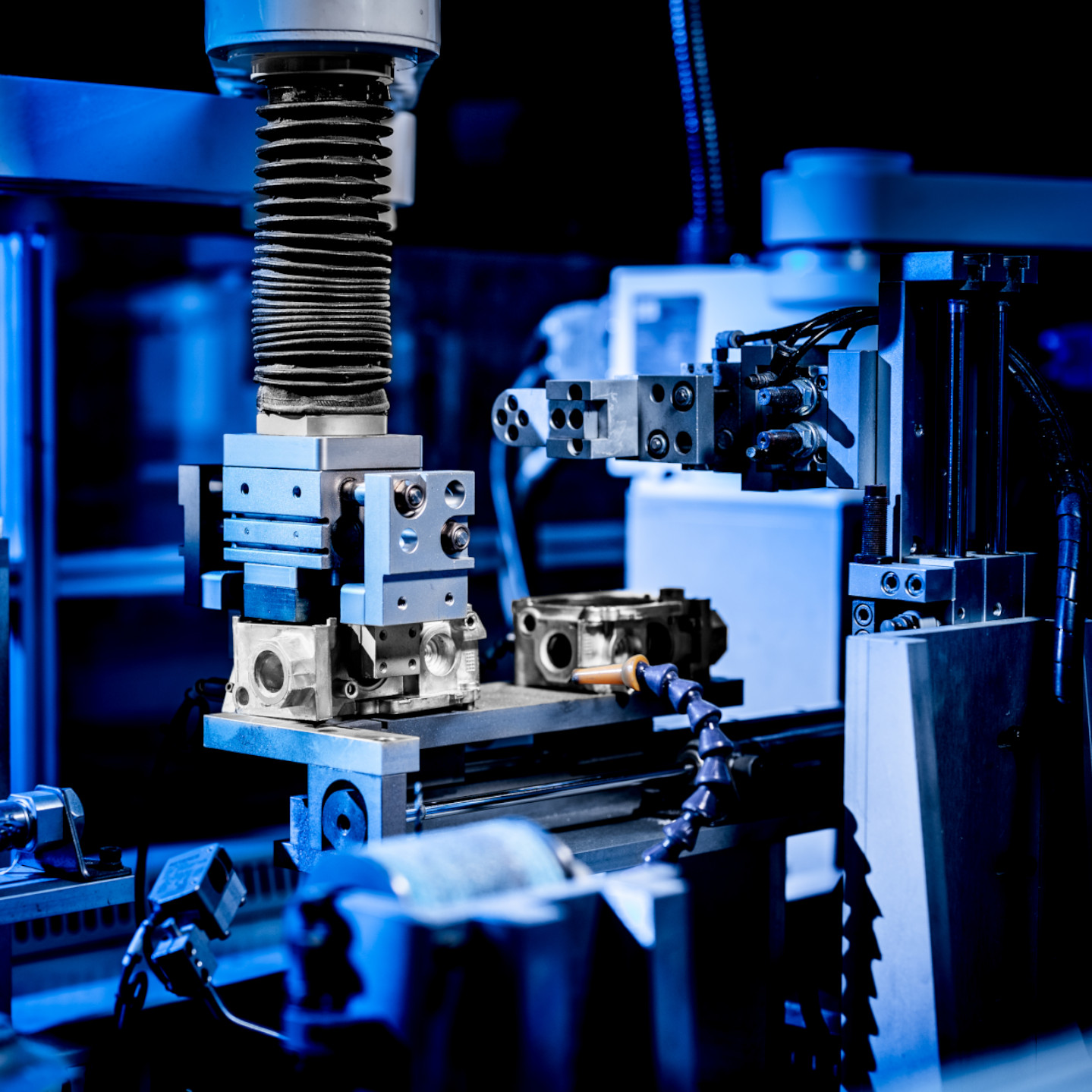

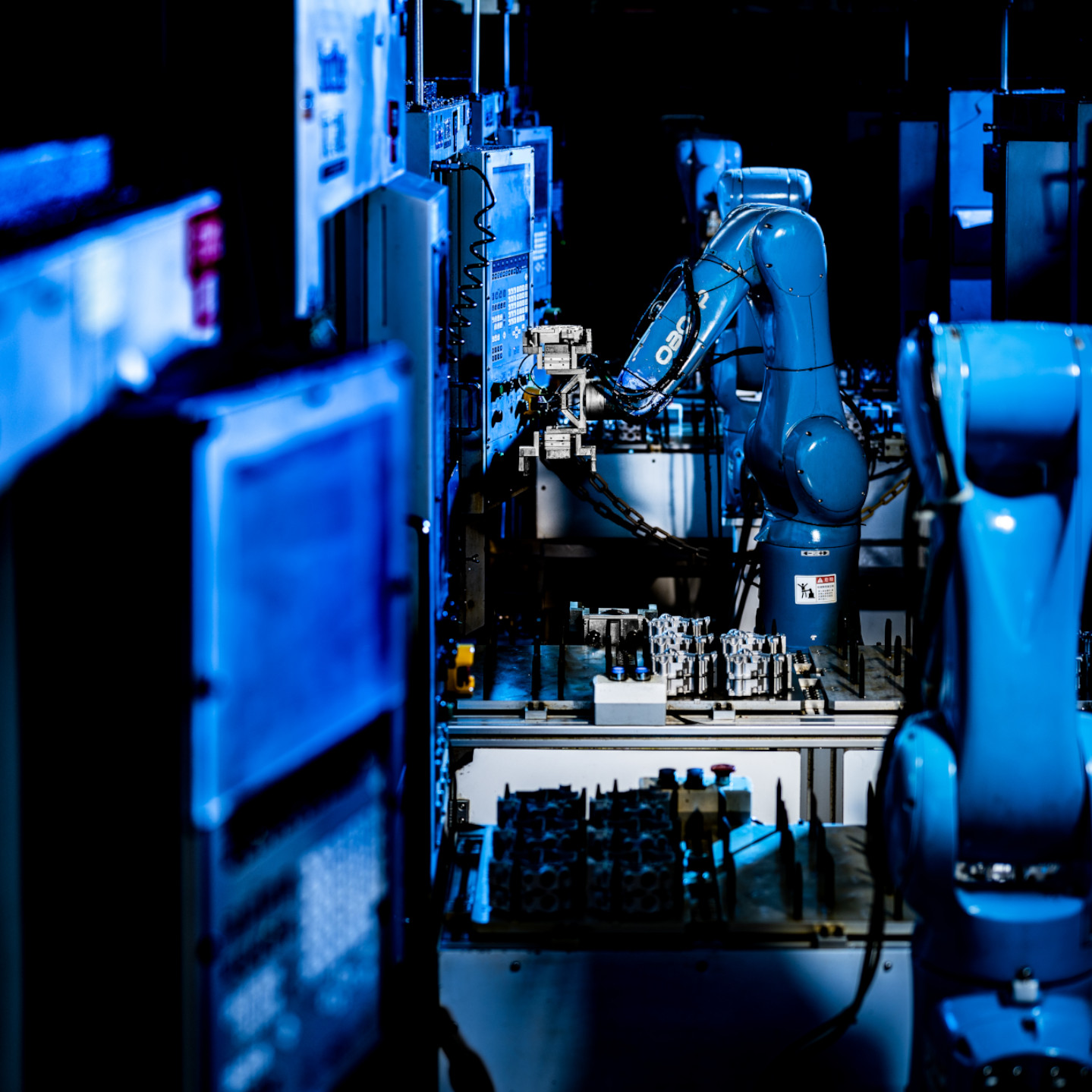

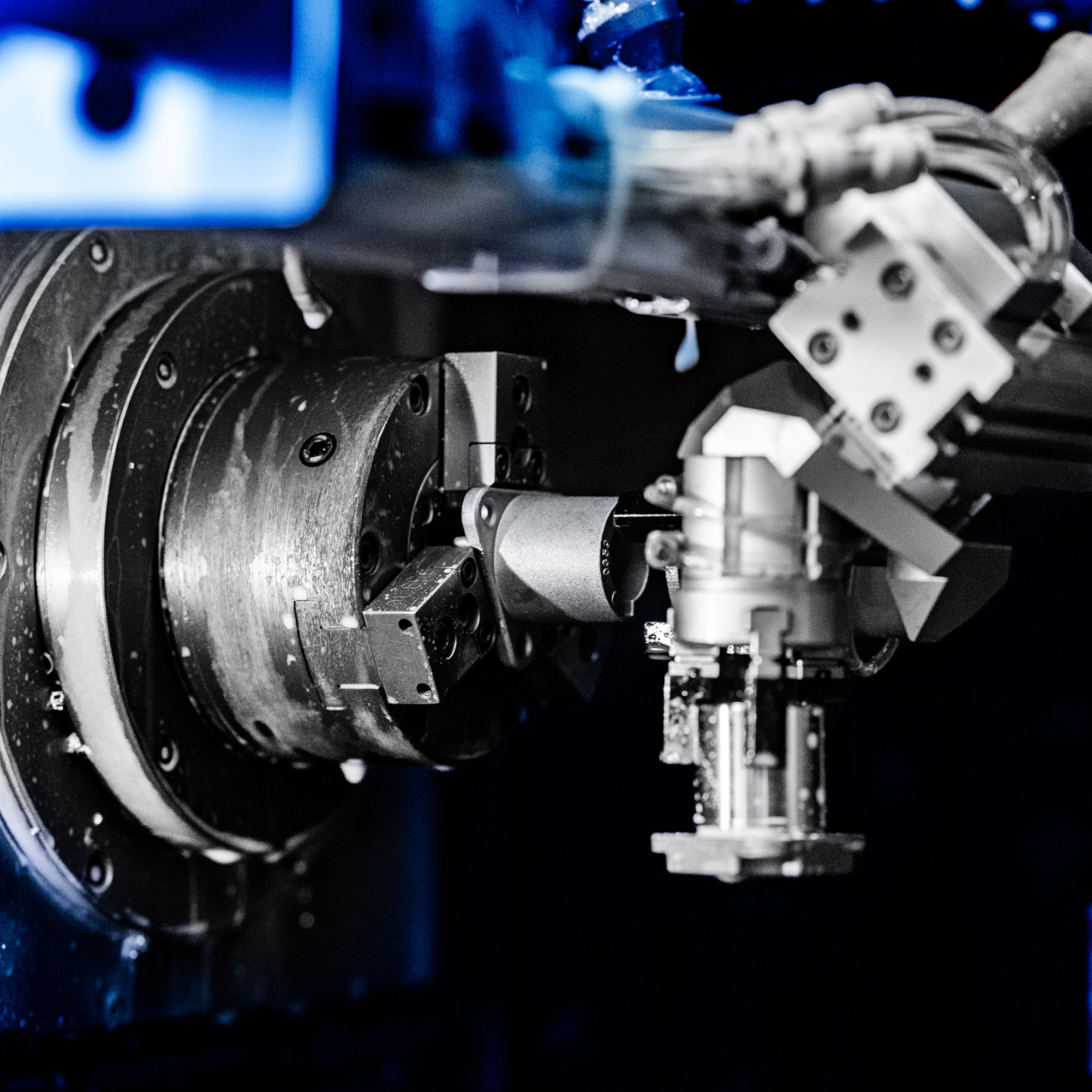

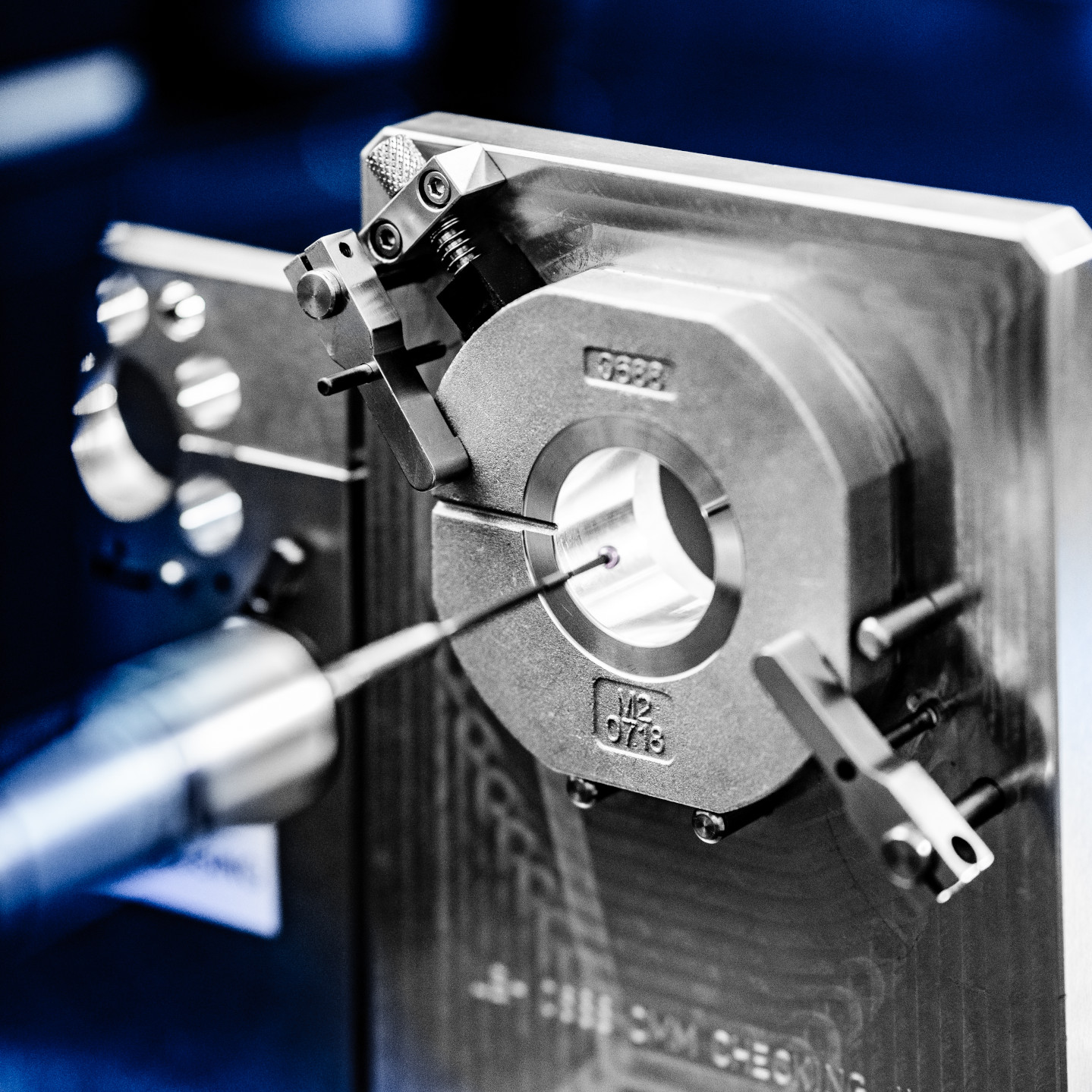

Solid Machining

At Engtek, we specialize in multi-axis CNC solid machining, a technique that involves cutting, drilling, and shaping solid materials to precise specifications. Our advanced equipment and experienced engineers allow us to provide unparalleled accuracy and precision in our machining services

Solid Machining

At Engtek, we specialize in multi-axis CNC solid machining, a technique that involves cutting, drilling, and shaping solid materials to precise specifications. Our advanced equipment and experienced engineers allow us to provide unparalleled accuracy and precision in our machining services

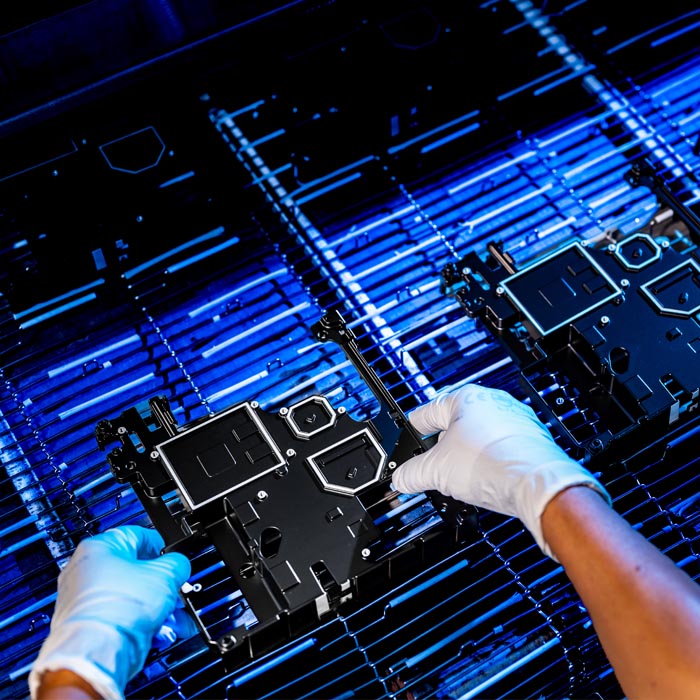

ENGCOAT®

A tailored suite of surface finish solutions, including Class 10K Clean room, automated washing line and a wide range of surface coatings, optimizes the performance, aesthetics while also exceed the stringent technical quality standards of our customers.

Surface Treatments

Electro-Disposition (ED) Coat, Powder Coat, Electroless Nickel (EN) Plating, Clear & Colored Anodizing, Chromate, Electropolish, Passivation

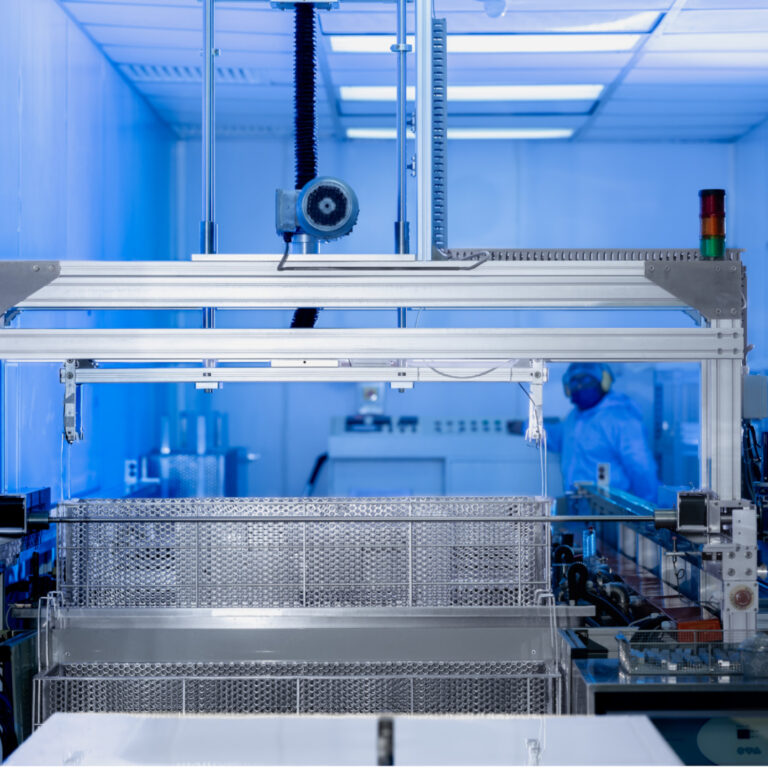

Precision Cleaning & packaging

At Engtek, we pride ourselves on our precision cleaning and packaging services that ensure our clients receive the highest cleanliness and most reliable products possible. Our advanced cleaning equipment are coupled with rigorous quality control measures to guarantee that our clients’ components are thoroughly cleaned of contaminants.

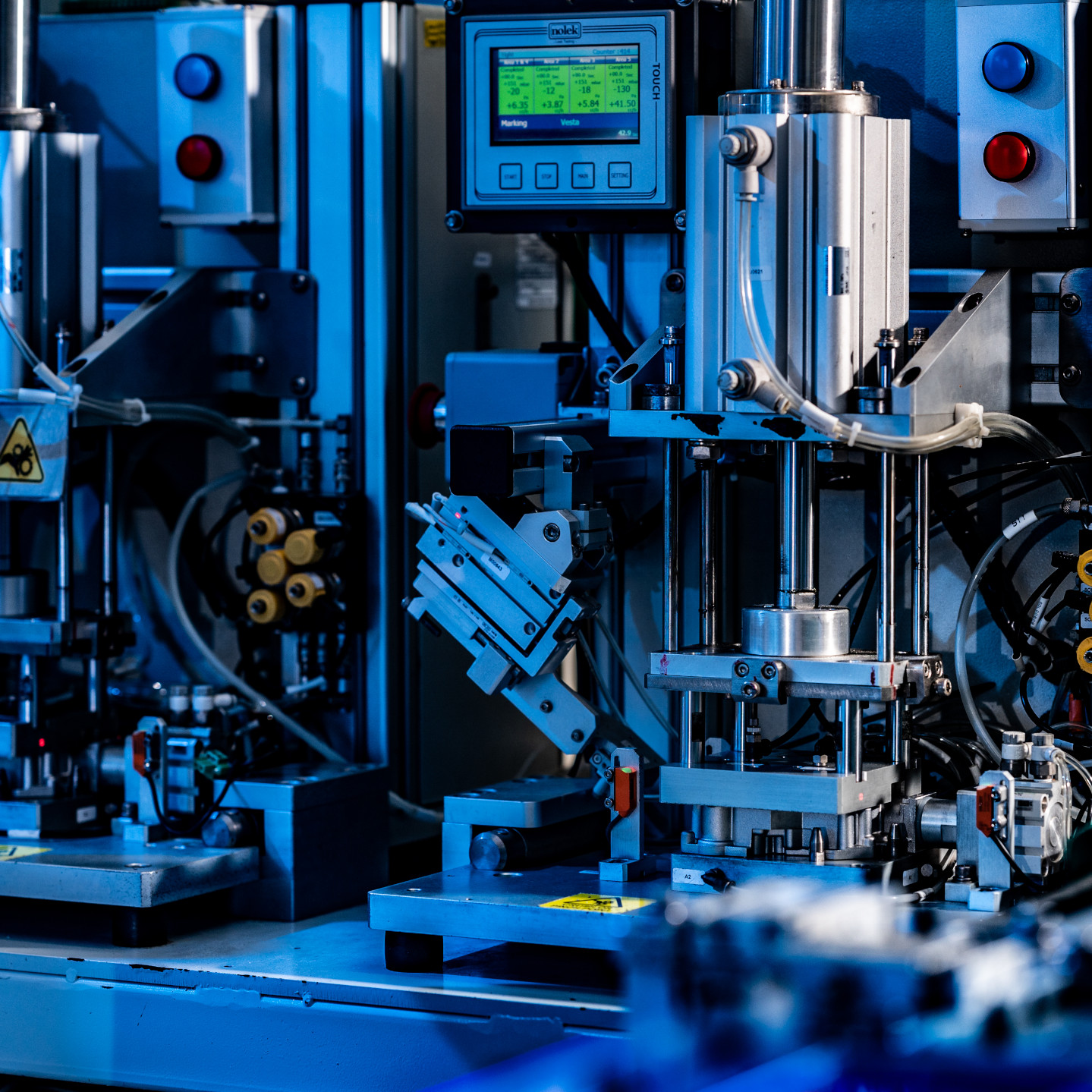

Assembly

We understand that our customers’ needs go beyond just machining and fabrication. That’s why we offer a one-stop center for assembly services, providing a hassle-free experience for our customers.

ENGASSY®

Assembly

We understand that our customers’ needs go beyond just machining and fabrication. That’s why we offer a one-stop center for assembly services, providing a hassle-free experience for our customers.

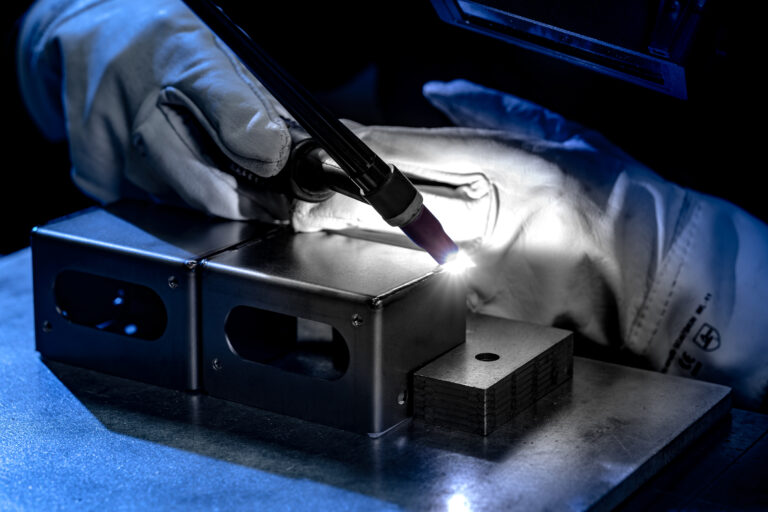

ENGFAB®

Sheet Metal Fabrication

- CNC Laser Cutting (accuracy ±0.1mm)

- CNC Hydraulic Press Brake Bending

- TIG Welding & MIG Welding

- Spot Weld & Laser Weld

Specialize in comprehensive sheet metal fabrication and finishing solutions, offering custom manufacturing solutions for metal components, molds, and hardware, as well as precision machining, assembly, and metal treatments, tailored to meet diverse industrial needs with high-quality standards.

New Product Introduction

At Engtek, we understand the importance of providing exceptional service to our customers. We know that time is of the essence in today’s fast-paced business world. That’s why we prioritize prompt RFQ responses, so our customers can make informed decisions quickly.

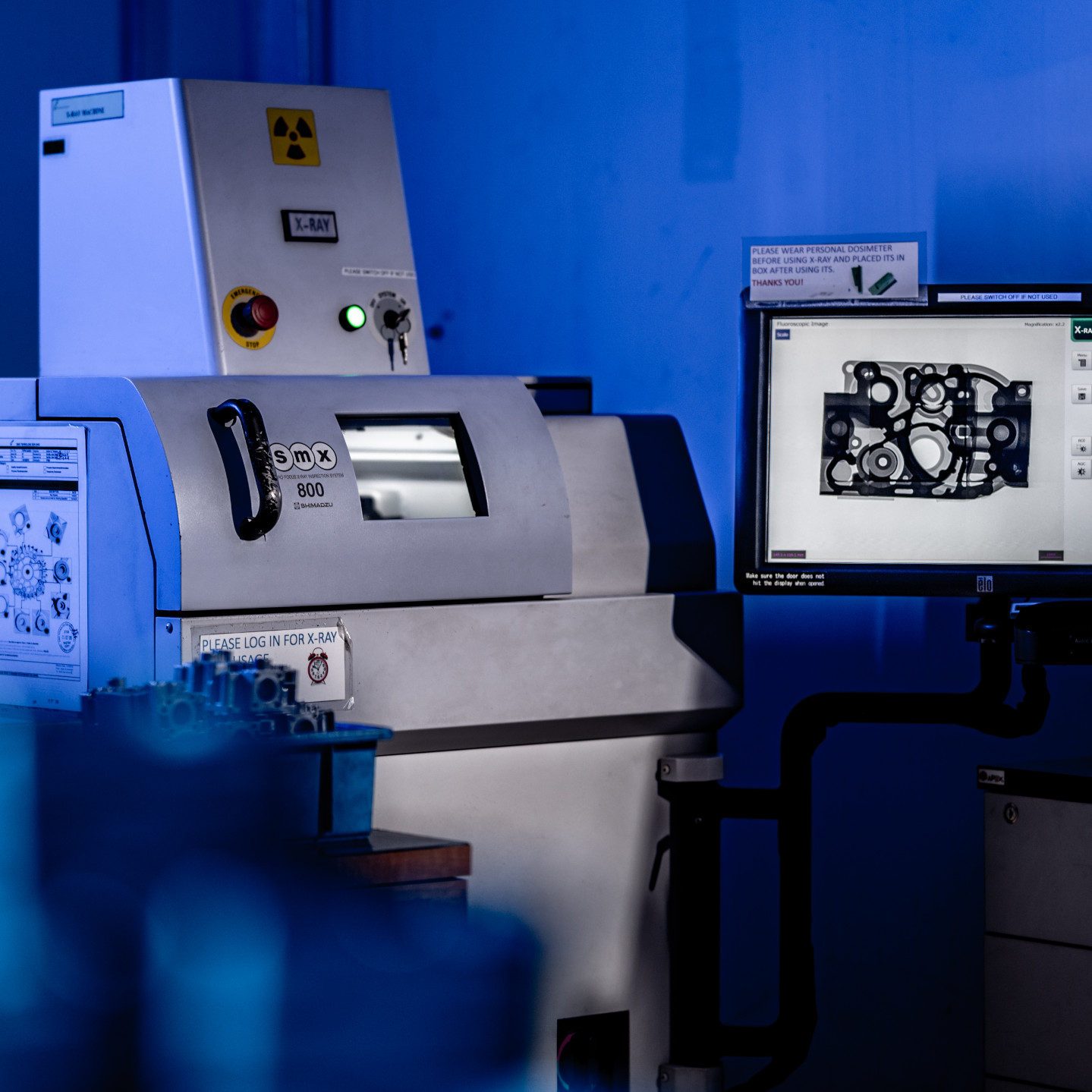

Quality Assurance & Testing

At Engtek, we take quality assurance and testing seriously. We understand that our customers rely on us to deliver products that meet the highest standards of quality and reliability, which is why we go above and beyond to ensure that our products meet their unique needs.